Written by @SmilexTech and translated by Giovanni Oppizzi

“We are extremely disappointed. Our engine is ten kilos lighter than 2016’s spec and we lowered the center of gravity by one centimeter, this are very satisfactory points in theory, but we can’t get it to work properly. We’ve chosen an aggressive route during winter and we’re now paying the price of that. During winter we ran numerous tests at the dyno with the mono-cylinder block, gathering promising data, but during assembly of the V6 unit some problems came to surface. We’ve been doing a lot of correlation work since January, crunching all the data that we get from track and dyno, but we need more time . We are working really hard in Sakura, working together with some external personnel, because time is of the essence. We work day and night, we don’t have time on our side. We have double the amount of wok ahed of us compare to our rivals and it’s very hard to do so without taking risks.”

Firstly we’ll discuss Hasegawa’s statement, which has caused some confusion, and then we’ll take a look at Honda’s PU and what’s wrong with it.

What many people are upset about is that Honda has used single cylinder engine during prototyping phases of the new engine. This is completely normal in F1. A one cylinder block in fact allows for a more precise and detailed analysis of the engine (fuel consumption, efficiency etc…), moreover it make it easier for engineers to understand the combustion chamber, which due to the introduction on HCCI Plus technology, has become even more important. Using this kind of test bench also simplifies making changes to PU, without wasting money and especially time. It’s the same idea behind using a scale model in the wind tunnel, it just makes more sense. Obviously it’s critical to have good correlation between the testing rig and the actual PU, this seems to be one of the problems at Honda.

Looking at the timeline of development for Honda’s 2017 PU ( internal name: ”RA617H”), the project started about a year ago, in April, working on the single cylinder block for the first 7 months. This makes sense, given the they completely reengineered the combustion chamber. For reference, in the picture below, we can see the timeline for Renault’s development. We can see that they spent 5 months on this phase. What Honda did differently, is they translated their work on the single cylinder into the full V6 version very late, only in December, giving them little time to find and fix flaws. This was partly due to the fact they had to engineer and implement HCCI technology on their own, without Mahle’s support, unlike Mercedes and Ferrari.

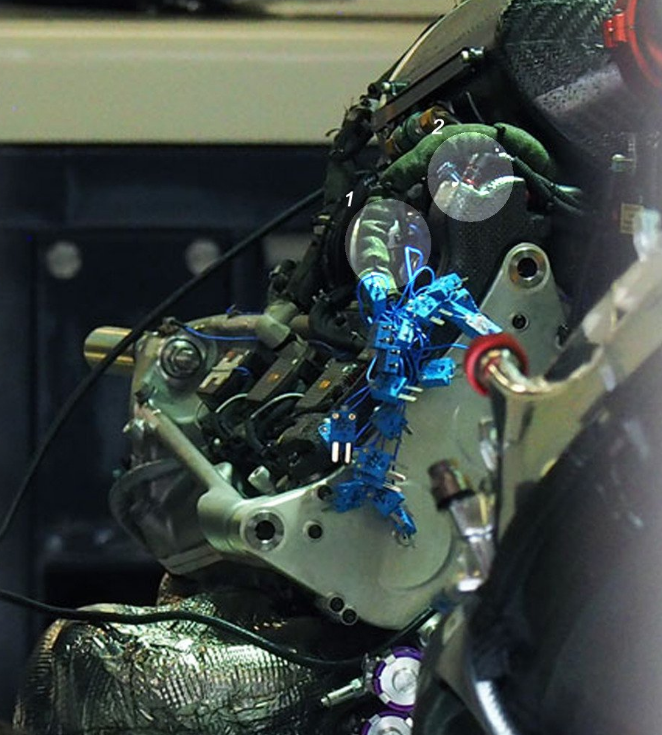

Also changed from 2016 is the positioning of the MGU-H in a lower part of the PU and the one of the compressor housing, now outside of the “V”, similar to what Mercedes did in 2014.

We shall now take a look at what are the problems of the new born power unit.

Starting from Barcelona, the firs issue was the positioning of the baffles inside the oil tank. This meant that in high G corners, the oil pump would starve, damaging the internals of the engine. Once the fixed this issue, other and more worrying ones came up. Honda is having big problems with managing vibration, this seems to be due to the HCCI system which is not where it’s supposed to be in terms of development. Beside these vibrations, they are also having trouble facing those coming for the curbs. This makes the whole care go into resonance and basically shake to pieces. The imperfect HCCI also causes improper exhaust flow, ruining performance of the whole PU (e.g. turbo).

To fix the HCCI problem, Honda will have to completely redesign the combustion chamber. This is what has Honda worried, because it could take many races before we see an update. Only time will tell.